-

MegoldásainkMegoldásaink

A Jungheinrich vezető vállalat.

- Iparágak

-

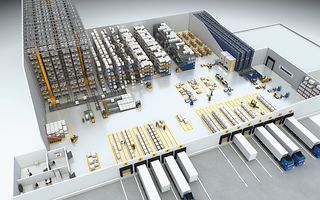

Alkalmazási területek

-

Automatizálás

Megoldásaink

-

Lítiumion technológia

Lítiumion technológia

Megoldásaink

-

Raktárbiztonság

Megoldásaink

-

Vevői referenciák

Megoldásaink

-

Innováció és kitekintés

Megoldásaink

-

TermékekTermékek

A Jungheinrich vezető vállalat.

- Targonca, raklapemelő

- AntOn by Jungheinrich

- Targoncabérlet

- Használt targoncák

- Automata anyagmozgató gépek

-

Akkumulátorok / töltési technika

Akkumulátorok / töltési technika

Termékek

-

Akkumulátorok

-

Töltési technológia

Töltési technológia

Akkumulátorok / töltési technika

-

Akkumulátorok

- Raktári állványrendszerek

- Raktárbiztonsági termékeink

-

Speciális megoldások

Termékek

- Ipari IT eszközök

-

AutomatizálásAutomatizálás

A Jungheinrich vezető vállalat.

-

SzolgáltatásokSzolgáltatások

A Jungheinrich vezető vállalat.

- Hibaelhárítás, javítás

-

Szerviz csomagok

- Jungheinrich eredeti alkatrészek & tartozékok

-

Energiaszolgáltatások targoncákhoz

Szolgáltatások

-

Energy management

Szolgáltatások

-

Használati utasítások

Szolgáltatások

-

Targoncabérlet

Szolgáltatások

-

Tréningek

-

Finanszírozás

-

Cégünk kulcs ágazata a szerviz

Szolgáltatások

-

AntOn by Jungheinrich szervizszolgáltatás

Szolgáltatások

-

Karrier

-

RólunkRólunk

A Jungheinrich vezető vállalat.

-

Elérhetőségeink

Rólunk

-

Telephely keresés

Rólunk

-

OKOSLOGISZTIKA MAGAZIN

Rólunk

- Aktuális témák

-

Tanúsítványok

Rólunk

-

Megfelelőség és fenntarthatóság

Rólunk

- Hírek - Események

- Innováció és kitekintés

-

Díjaink

Rólunk

-

Elérhetőségeink

-

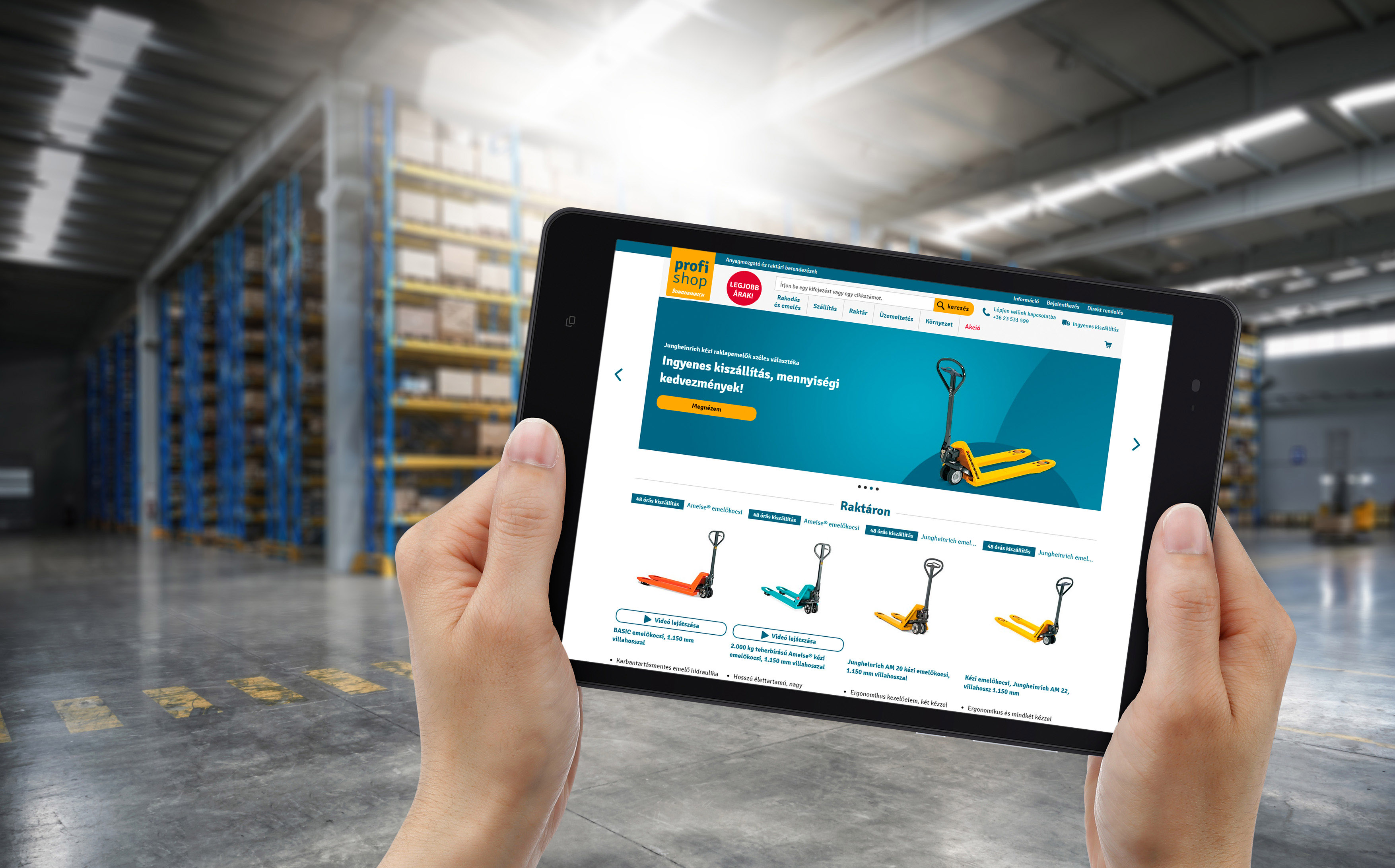

ShopShop

A Jungheinrich vezető vállalat.

-

Emelőkocsik, raklapemelők

Shop

-

Targoncák

Shop

-

Emelőeszközök

Shop

-

Szállítóeszközök

Shop

-

Üzemeltetés, üzemi felszerelés

Shop

-

Tisztítás, takarítás

Shop

-

ÁSZF PROFISHOP

Shop

-

Emelőkocsik, raklapemelők